Microencapsulation technology – a way forward in the food supplement industry

Microencapsulation is an innovative technique which allows a compound to be encapsulated inside a tiny sphere known as microcapsule. These microcapsules release their contents at appropriate time by using different release mechanisms.

It's a technology needed to protect the activity of a compound as it provides a safe delivery of the compound to the lower gut without being destroyed.

Microencapsulation solves problems

Among the food supplements, there are substances that are poorly soluble in water, sensitive to decomposition with gastric acid, taste bad and have a low degree of absorption, are susceptible to self-decomposition and oxidation, etc.

Microencapsulation can successfully address these challenges in food supplements containing coenzyme Q10, vitamins, minerals, CBD, or other plant extracts.

What are the benefits of the microencapsulation?

- Thermostability enhancement

- Bioactive compound protection

- Controlled release

- Volatiles maintaining

- Odour shelter

- Texture/sense improvement

- Better bioavailability of the active ingredient

- Improved absorption

- Better stability of the product

An innovative process for the microencapsulation of food supplements

Biostile, in collaboration with Slovenian researchers and scientists, has developed the Biostile Microencapsulation technology® based on complex coacervation.

The desired ingredient is dissolved in the oil phase and surrounded by a coating (a combination of natural polysaccharides and proteins). This creates microcapsules, where the desired substance is dissolved in a drop of oil and a coating is formed around it to prevent degradation in acidic pH conditions.

Then, using an innovative and patented freeze-drying process, the microcapsules are deep-frozen and slowly vacuum-dried to a dry powder form.

This method allows the entire microcapsule preparation process to be carried out at low temperatures and is also suitable for heat-sensitive substances.

Thus, durable dry microcapsules in powder form are obtained, which are used for final product formulation and capsule filling. All the materials used are made from naturally sourced ingredients and are also suitable for vegans.

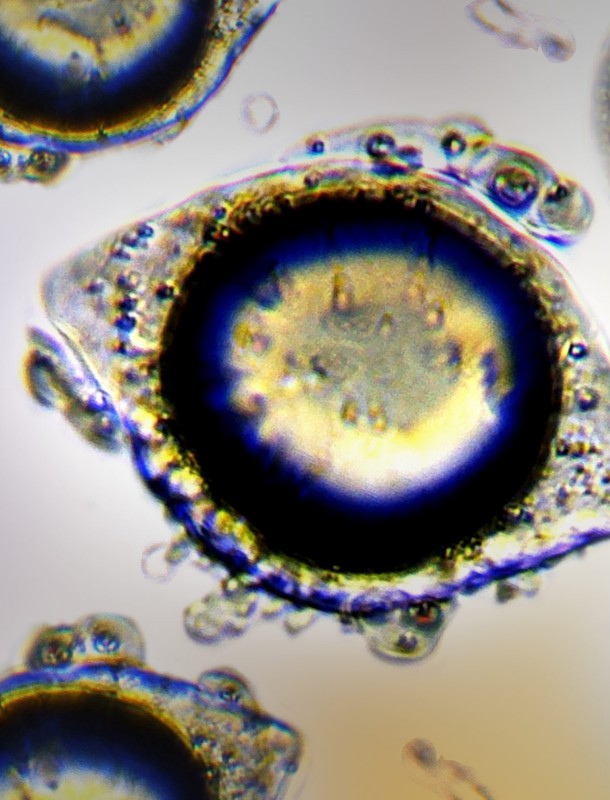

Coacervate microcapsule (pictured above), visible under a light microscope. A drop of olive oil in which the coenzyme Q10 is dissolved, surrounded by a wall of polysaccharides and proteins that protects the oil phase from external influences and is resistant to dissolution in acidic environments. The wall only breaks down in the presence of pancreatic enzymes, releasing the internal oil phase. Thus, controlled release in the gastrointestinal tract and a high bioavailability and absorption rate are achieved.

In which products do we use the BMT® technology?

We use BMT® Biostile microencapsulation technology to produce food supplements containing coenzyme Q10, vitamin D3, curcumin, resveratrol, cannabidiol (CBD) and vitamin C.

Why choose microencapsulation technology?

The most important effect achieved by microencapsulation technology is the protection of the active ingredient. Passing through human digestive system, the outer layers of microcapsules might be dissolved in gastric acid at lower pH, then the core substances are released and absorbed in the small intestine which enables better effectiveness of the core ingredients.